Toll Blending and Contract Manufacturing

Toll Blending is Challenge Chemicals’ fastest growing sector and draws on our experience of 50 years of manufacturing.

Challenge Chemicals has full capabilities for toll blending services. We manufacture finished chemical products to many of Australia’s companies large and small in a variety of industries including mining, agriculture, automotive, industrial, health care, water treatment and much more. We can handle and blend with most classes of Dangerous Goods or hazardous chemicals and have the expertise to blend product economically, safely and accurately. We have forged a reputation for timely and cost effective delivery of blending services.

Our end-to-end capability facilitates the creation of a bespoke product range under your brand. Targeted to specific needs, formulated for a specific purpose, labelled with your name, as the exclusive retailer to keep customers coming back for your signature range.

A business that evolves and grows is an agile, diversified one.

Expanding your product and service offering with a unique product range; either sold direct toyour consumer, or used in your unique business operations, gives you a competitive edge andaccess to new markets.

Challenge capital limitations. Expect more expertise, innovation and operational support to complement your business capabilities.

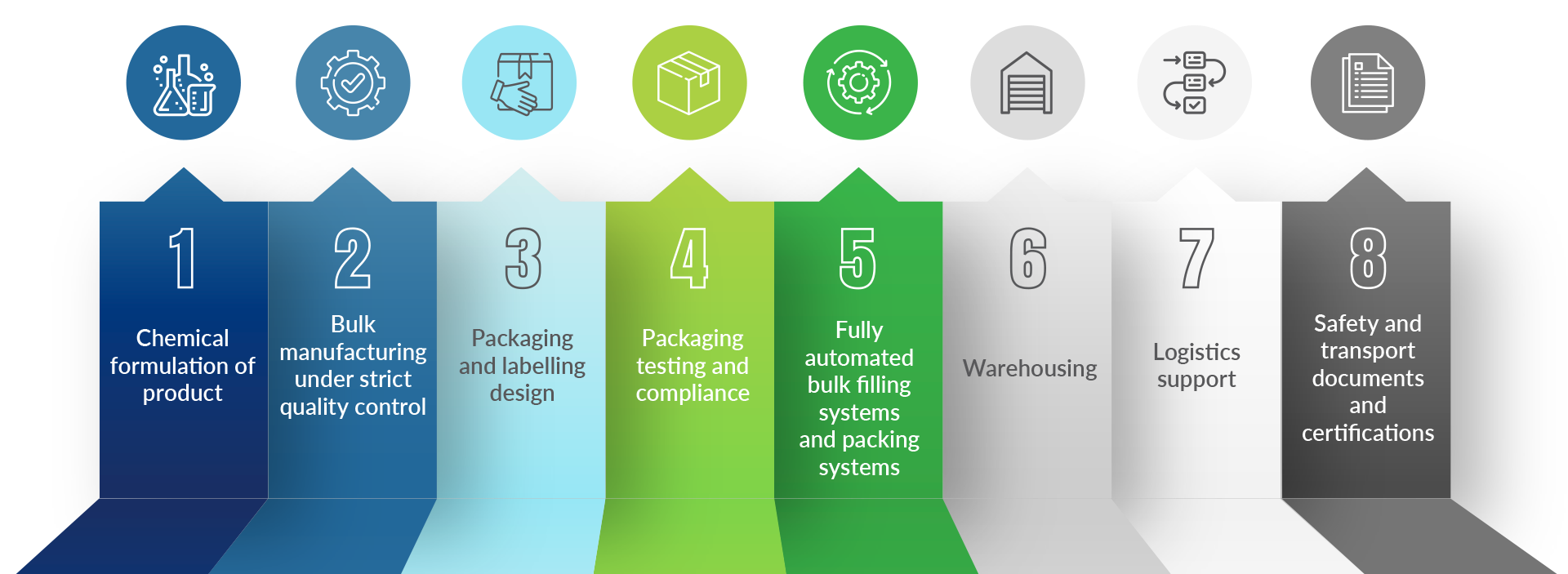

The Complete Process

Challenge Chemicals has the experience and reliability to guide you openly and expertly throughout the Toll Blending journey, taking your product as far as you want it to go. Our combined 40+ years of experience and knowledge in chemical manufacturing is imbedded into our business processes and shared with all our technicians.

Using specialized equipment and expert mixes, processes, and produces we create a unique, new product specific to your formulation requirements. Beyond manufacture, Challenge Chemicals deliver additional services such as packaging, labelling, and logistics. This means you can take your niche product as far as you need it to go, building a new commercial stream into your business.

Our Capabilities

Challenge Chemicals commits to constantly pushing the boundaries to offer advanced chemical solutions that redefine efficiency and effectiveness.

Our capability extends beyond manufacturing, encompassing formulation, packaging design, testing, and logistics, positioning us as an integral supplier for a plethora of industries, including mining, healthcare, agriculture, and more.

At our core are four key service areas:

- Toll Blending, Toll Filling and Warehousing

- Manufacture and supply of our signature, Challenge Chemicals branded range

- Distribution of our unique, Pilbara Tough range of products

- Supply of bulk raw chemicals at competitive price

From small-scale tasks to Australia’s largest projects, our expansive services have stamped a mark of quality and reliability.

Our expansive facilities and custom designed equipment set the standard for manufacturing and safety.

Large scale, licensed bulk storage capacity offers short term solutions and coordinated logistics. Our warehousing offers more than 800 under cover pallet spaces and more than 4000m2 of storage capacity for bulk materials.

Custom formulations

Custom formulations Compressive formula portfolio

Compressive formula portfolio Bulk volumes up to 20,000L

Bulk volumes up to 20,000L Stringent batch quantity control

Stringent batch quantity control Global buying power

Global buying power BSI 9001 2015 Quality Management Systems

BSI 9001 2015 Quality Management Systems

Large Scale Filling & Warehousing

Challenge Chemicals has large scale chemical liquid blending capability, from 1000L up to 20,000L. As well as the liquid solutions, our bulk powder blending machines mean we are also capable of producing large volumes of finished powder products.

Our Dangerous Goods licenses facilitate on site storage and manufacture for a wide and varied range of products, well protected by environmental and stringent safety procedures set in place. Our experience, knowledge, outstanding team, and site capabilities are set to take on any demand, small or large, to meet any project needs.

Whether you require full-service toll blending or simply filling, our custom designed and built toll filling equipment means we are capable of handling small and large volumes.

Custom packaging

In-Mold-Labelling packaging for volume orders

Custom, automated filling and labelling, capping and batch coding

Certified packaging engineering and testing

Specialised shelf ready packaging from 500mls to 5L

From 15L to 1000L IBC and iso tanker filling